No products in the cart.

Too – tall and dense vegetation will block sunlight.

Solar panels will receive less solar radiation. Since the amount of electricity generated is directly related to the intensity of solar radiation, when the radiation amount is reduced, the power generation capacity will decrease.

For example, if we don’t clear the surrounding vegetation of a large photovoltaic power station in time, the blocking area will expand and the power generation efficiency will be significantly reduced.

Grass and trees affect the heat dissipation of the panel.

When the battery panel is working, it will generate heat, which needs to be dissipated to maintain normal temperature.

Dense vegetation around it blocks air circulation and worsens the heat dissipation effect.

If the temperature of the battery panel is too high, the internal resistance will increase, the power generation efficiency will decrease, and the lifespan may also be affected.

In the hot summer, due to poor heat dissipation, the temperature of the panel rises rapidly, the power generation efficiency drops significantly, and it may even malfunction, increasing operating costs.

Grass growth makes maintenance costlier and more difficult.

On the one hand, we must clear vegetation regularly. This increases the cost of manpower, material resources, and time. Maintenance personnel need to use specialized tools and equipment and may have to do frequent maintenance.

On the other hand, vegetation grows irregularly, which complicates maintenance. Tall vegetation needs special equipment to clean, and we must be careful not to damage battery panels and other equipment.

Traditional weeding equipment mostly requires manual operation.

The labor intensity is high and the working speed is slow.

In large power plants, weeding is time-consuming and laborious.

For example, using a sickle or a small lawn mower manually cannot clear much area in a day and cannot keep up with the growth rate of vegetation.

Solar farm terrain can be complex. Specifically, there are ups and downs, slopes, etc. Consequently, traditional equipment is difficult to adapt to. For example, operation on slopes is difficult and even poses safety risks. Moreover, equipment cannot fit into narrow spaces or corners, thus resulting in incomplete weeding.

When operating traditional equipment, power generation equipment may be damaged due to inexperience or negligence.

Weeding close to photovoltaic panels can easily scratch them, affecting normal operation and lifespan.

Because traditional lawn mowers have a simple structure, they are prone to breakdown. Requires frequent maintenance.

Increase maintenance costs and affect weeding progress.

A large number of workers are required, resulting in high labor costs.

Fuel consumption and parts replacement costs are high.

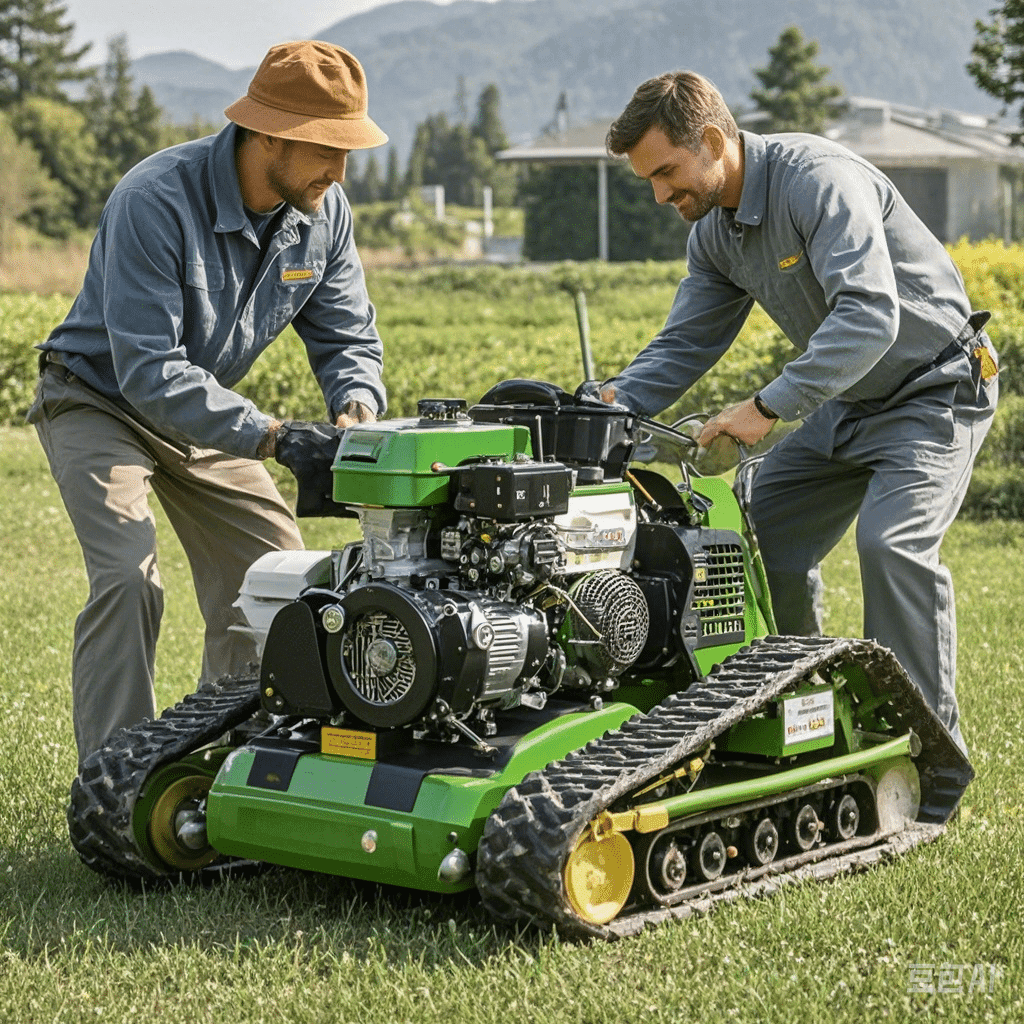

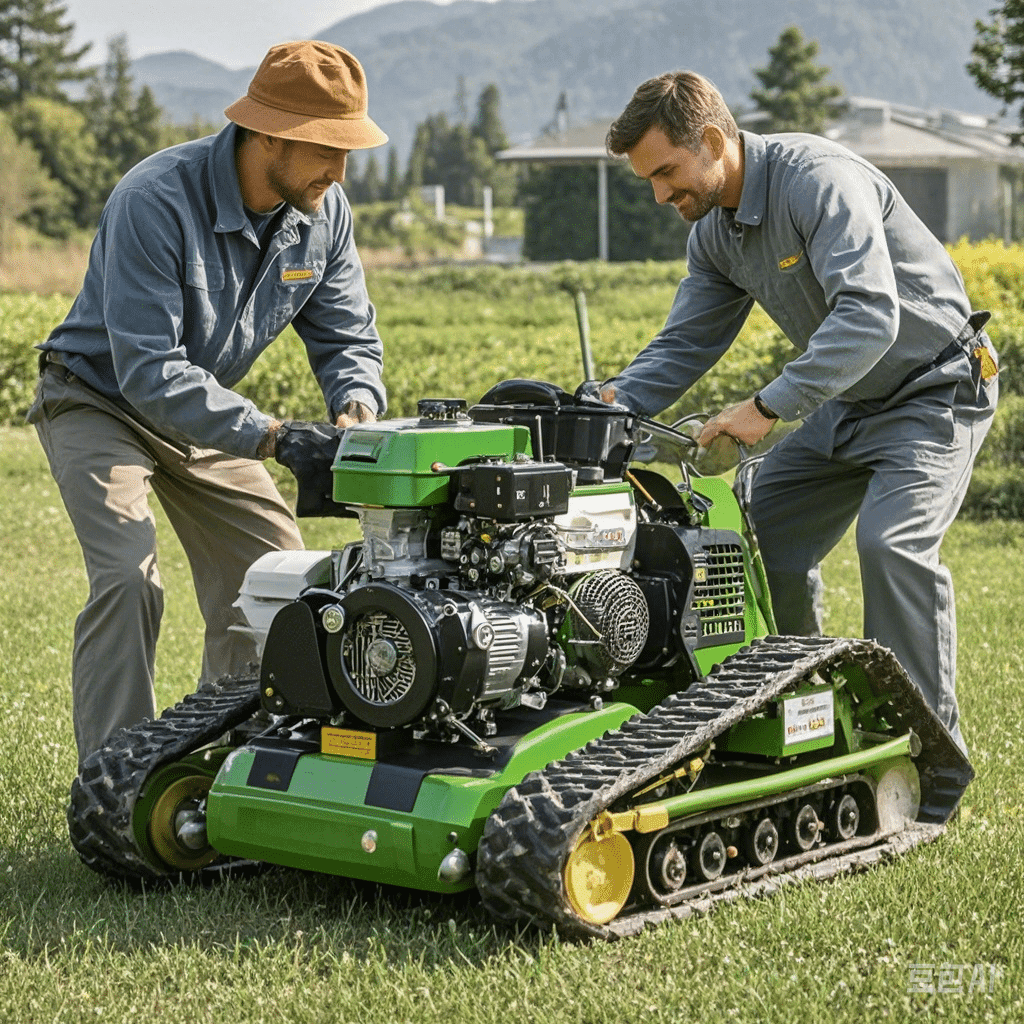

The remote control lawn mower equips track components. This design enables it to easily adapt to uneven ground grooves. Whether at a solar photovoltaic power plant’s rugged ground or in complex terrains, the remote – control lawn mower can effectively move and conduct weeding operations. The tracks’ strong grip ensures the machine’s stability in various terrains. Uneven ground doesn’t affect it like traditional weeding equipment’s running wheels do. For example, in some sloping areas, the remote – control lawn mower’s tracks can firmly grip the ground, preventing the machine from slipping and ensuring smooth weeding work.

Remote controlled lawn mowers are extremely efficient at cutting weeds. One machine is equivalent to the workload of thirty people. Such efficient weeding capabilities can quickly clear weeds in solar photovoltaic power plants, reduce the impact of weeds on photovoltaic modules, and improve power generation efficiency. At the same time, efficient weeding operations also save time and labor costs, bringing great convenience to the operation of photovoltaic power plants.

Remote control operation is a major advantage of remote control lawn mowers. It realizes the separation of people and vehicles, which greatly improves the safety of operations. The remote control signal has a wide coverage range, up to 200 meters. Workers can operate the lawn mower from a safe distance, avoiding the possible dangers caused by direct contact with the machine. In addition, the remote control lawn mower is also designed with an anti-splash cutterhead baffle to prevent the cutterhead from splashing gravel, glass flakes, hardwood, etc. when cutting, further enhancing safety protection. This safe and reliable design makes the remote control lawn mower more secure to use in solar photovoltaic power plants and other places.

We make the main body of the remote – control lawn mower from high – strength steel. This ensures its stability and durability in various complex environments. The main body connects various components and provides a support structure for the whole machine. Meanwhile, we design the main part with a reasonable layout, which facilitates operators’ remote operation and maintenance.

Motor drive: We mostly drive remote – control lawn mowers with motors, using brushless DC motors. This type of motor is energy – saving, durable, and suitable for long – term work. For example, some remote – control lawn mowers are equipped with motors from CNC machine tools’ brushless DC motors, providing powerful power for the mower.

Gas – electric hybrid power: Some remote – control lawn mowers use gas – electric hybrid power. They have their own power generation and power supply systems and auto – charge during operation. Remote – control lawn mowers equipped with Loncin gasoline engines can achieve gasoline – and – electricity hybrid driving during operation, improving the machine’s endurance and work efficiency.

Strong grip: Remote control lawn mowers usually have tracks designed with heightened teeth. They grip strongly when walking on steep slopes and can move easily and quickly. For example, when a remote – controlled lawn mower works on a 45 – degree slope, its tracks can grip the slope strongly to ensure the machine’s stable operation.

Autonomous deviation correction device: The crawler – type remote control lawn mower has an autonomous deviation correction device. It can automatically correct the deviation when it goes off the route. This function ensures the machine’s walking accuracy during operation and improves work quality.

Grass – crushing function: The remote – control lawn mower has a grass – crushing function. This means it can cut the grass without the grass being visible. Moreover, after being spread on the ground for a long time, the powdered grass can turn into fertilizer. Then, the grass can nourish the ground, fully meeting the requirements of modern agriculture.

Cutting method: Regarding different terrains, the remote – control lawn mower can use horizontal cutting and vertical knife – throwing methods.

Battery control device of remote – control lawn mower: It has several components, namely battery holder, cover, battery, relay, output line, and switch assembly. Additionally, the start/special keys can prevent the accidental touch of the switch, thereby enhancing safety.

Remote – control lawn mower batteries: These batteries have different specifications such as capacity, voltage, internal resistance, etc. Moreover, they can meet various user needs.

Remote control lawn mowers have numerous advantages in solar photovoltaic power stations. Firstly, they improve weeding efficiency significantly. Moreover, they ensure the performance of photovoltaic modules effectively. In addition, they can solve the problem of equipment heat dissipation. Furthermore, they change the operation and maintenance status of the power station. As technology keeps advancing continuously, consequently, they will play an even more important role in the field of photovoltaic power generation in the future.

For more product demonstrations, please follow Youtube

Not only will we redefine our customers’ business models, but we will also redefine the OEM-dealer relationship, in other words, we will always have your back.